BOOSTING INCIDENTS

Per OSHA Regulations, all mobile equipment must be equipped with continuously operating strobe lights that allow workers to see parked vehicles in dark areas.

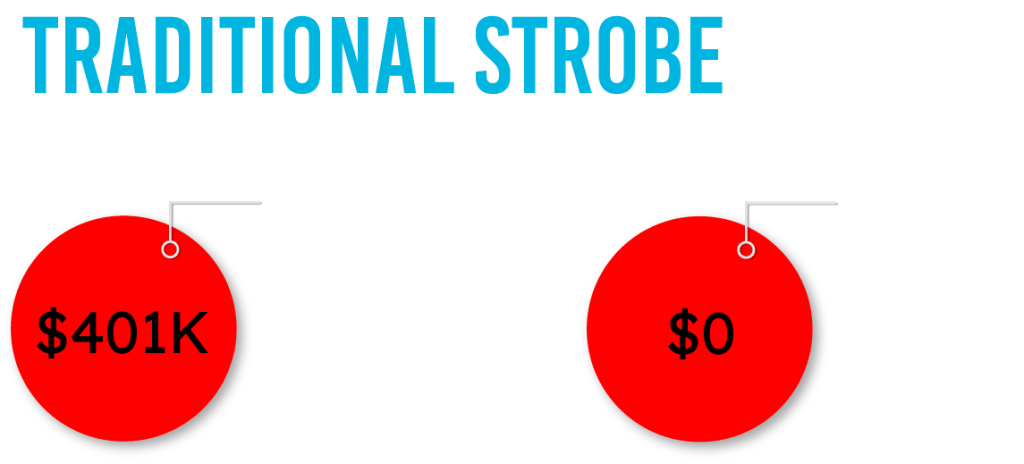

The Traditional Strobe lights discharge the main vehicle battery as it is parked. A fully discharged battery requires boosting or replacement, leading to production downtime, higher safety risk and additional maintenance costs.

Installing Smart Mining Strobes eliminates 100% of annual maintenance costs up to or even over $401,760 related to boosting or replacing incidents.

BOOSTING INCIDENT COST BREAKDOWN

| UNIT | QTY | CONT/UNIT | TOTAL COST | |||

| DIRECT COSTS | LABOUR COST | hrs | 3 | 150 | $450 | |

| HARDWARE COST | each | 0.33 | 200 | $66 | ||

| INDIRECT COSTS | PRODUCTION DOWNTIME | hrs | 4 | 150 | $600 |

| TOTAL COST/BOOSTING INCIDENT | $1,116 | TOTAL AVG ANNUAL COST/MINE | |

| INDIRECT COSTS | 360 | $401,760 |

SMART VS TRADITIONAL: SAVE